While starting up a new FX-CLv2 chlorine analyzer we sometimes get a call for help from a customer: "I need to return this analyzer. I calibrated, it was running fine, and then the motor stopped. My old FX-1000P didn't do this, what's wrong?"

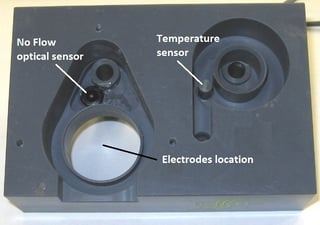

First we explain the analyzer is working as designed - the No Flow sensor in the measuring cell didn't detect sufficient flow to the measuring cell, so it signaled the processor to turn off the mixing/stirring motor. The buffer feed motor is also turned off during no flow conditions so as not to waste the pH buffer.

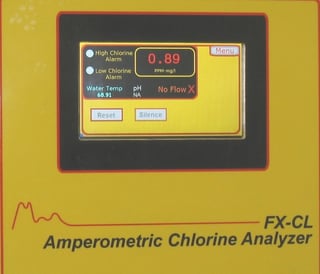

It also displays a "No Flow X" alarm on the local touch screen display.

It also energizes the no flow alarm relay, indicated by the LED, to alert you to the flow interruption via your SCADA or remote monitoring system:

After hearing this, the customer will usually say that their old analyzer didn't do this, and they'd like the old style instead. Why is this included anyway? Can we bypass this?

The customer is right, the "old" FX-1000P did not have a no flow sensor; when flow was lost, usually due to a bubble blockage, the motor kept running. The customer wouldn't realize there was a problem until......

Without a continuous supply of water the electrode eventually overheats. The measuring electrode expands due to thermal expansion, the gold tube portion of the electrode then cracks or distorts, causing a water leak between the gold tube and copper post on which it's mounted.

This "short circuit" would cause constant, wildly fluctuating residual readings, prompting a tech support call. After a few questions examination of the electrode would confirm it was destroyed and required replacement, costing over $1,000 dollars.

When we started the re-design of our FX-1000p chlorine analyzer to the digital FX-CLv2, we attempted to resolve or avoid as many issues as possible to make the new analyzer as trouble-free as possible.

We included the optical No Flow sensor in the measuring cell to prevent destruction of the measuring electrode. It works as stated above with an interruption in flow; when flow is restored it turns both motors on, resets the no flow alarm, and displays that flow is restored on the touch screen display with the blue water drop and "FLOW" message.

To the question of "can this sensor be bypassed?", the answer is yes, but you'll first need to sign a waiver to confirm that you want this safety device disabled and will be responsible for the cost of a positive measuring electrode replacement, even during the warranty period.

Their "old analyzer" on the same sample stream probably did experience similar blockages; except that without the sensor and alarm present they didn't know it until the residual dropped to near zero (due to the chlorine being consumed at the electrode and not being replaced) or the electrode was damaged.

So why are the blockages occurring for some customers, or only in certain locations? Usually the flow interruption is caused by a collection of air or gas bubbles that block water entry into the measuring cell. Bubbles can be caused by a pump cycling off and on, but this typically occurs when sampling groundwater with entrained gas or air bubbles. We don't usually see this issue with surface water or wet well monitoring. As the water rises from the well or aquifer, it de-pressurizes, any micro-bubbles present expand in size and collect in the port in the lower block that holds the measuring electrode.

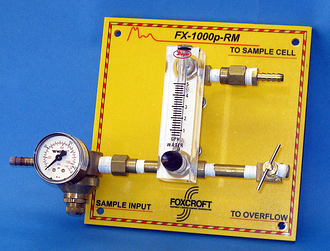

The solution is to use the overflow bypass fitting provided with each new system, or to use the fitting in combination with our flow rotometer.

Occasionally we encounter flow reduction or blockage in chlorine analyzers monitoring certain groundwater sources.

Occasionally we encounter flow reduction or blockage in chlorine analyzers monitoring certain groundwater sources.