While calibrating your FX-CLv2 chlorine analyzer you've seen values for "VDC" along with the PPM residual readings. What is VDC and why is it shown?

In an amperometric chlorine analyzer a voltage is applied to the measuring cell. When chlorine, or any other oxidizing substance, contacts the positive measuring electrode it oxidizes and produces a current. This current is proportional to the concentration of chlorine in the water sample.

The VDC, or volts DC, is a measure of this current generated by oxidation in the sample from which the residual measurement in parts per million (PPM) is produced. The total possible voltage range of the system is 5 volts.

What are the numbers on the calibration screen?

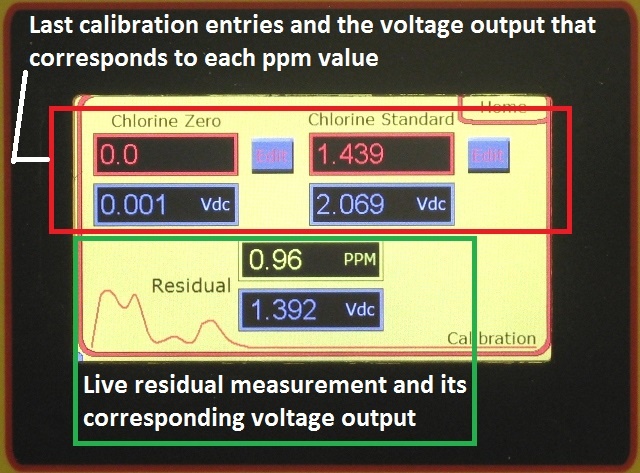

The calibration screen below shows three sets of numbers:

Top left "Chlorine Zero": Zero Point value in PPM entered at the last calibration, and the VDC measured when it was last set.

Top right "Chlorine Standard": the last Standard (span or grab sample result) calibration value in PPM entered, and the VDC measured when it was last set.

Bottom Center "Residual": Live readings in PPM and the associated VDC which are producing the PPM result. Note that this measurement is determined by the slope set by the last calibration.

When calibrating you are defining two points within the analyzer's operating range, usually 0-5 PPM. The first point is zero, the second is the residual typically measured with a portable colorometric chlorine analyzer. These two points define a linear slope, every X amount of voltage is equal to Y PPM up to the limit of the operating range.

There should be near zero volts being produced when you set the zero point. However, many water sources produce a "background voltage" even when no chlorine is present, so you may never reach zero volts in your calibration.

Not to worry, when you notice the VDC stabilizes at it's lowest level and you enter 0.00 PPM, you shift the zero point up to that voltage level, effectively cancelling out the background voltage. Any measurement beyond that point will be produced by chlorine.

The Analyzer Will Do What You Tell It To Do Via Calibration

It's important to remember with digital measurements that the operating software, like a computer, will do what you tell it to do through your calibration values.

One customer's analyzer always produced 0 PPM: Chlorine Zero was set as 0.00 PPM as required. The Chlorine Standard was also entered as 0.00 PPM. When they returned to the Home run screen they and their SCADA saw the analyzer always measuring 0.00 PPM chlorine. They had defined the output to be zero, which is what they got.

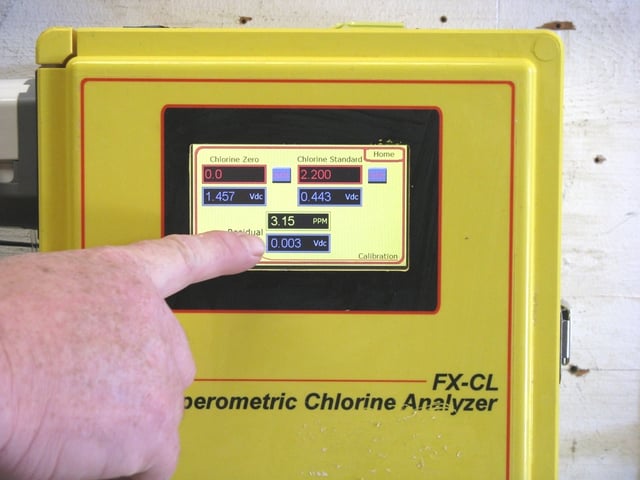

Another calibrated a negative slope as shown below. Since the operating software assumes a positive slope, negative slopes can produce unpredictable, incorrect results.

Below, the live reading produced was seen when we were feeding de-chlorinated water to set the zero point. Note the very low 0.003 VDC produced by zero chlorine in the sample produced a large 3.15 PPM residual measurement.

In the last calibration, the 1.457 VDC indicates there was chlorine in the sample when the zero point was set; this value should be 0.050 VDC or less when you enter "0.00". You'll note the 0.443VDC when 2.200 PPM was entered.

Why Is VDC Displayed?

The VDC is included as a calibration guide and trouble shooting tool. A wastewater customer's analyzer was measuring almost 5PPM of chlorine being discharged from the plant while grab sample and lab results showed negligible levels of chlorine. The state DEP investigated and found that an industrial customer was illegally dumping manganese into their waste stream. In this case the analyzer was able to detect a substance that the colorometric instruments could not.

Final Tips

-

Don't obsess over the VDC, but paying attention to it can show if a calibration was entered properly, or indicate a problem if grab sample results don't look right or match the analyzer readings.

- For the highest resolution and less erratic readings, there should be a significant difference in VDC between your zero and PPM entries when calibrating your analyzer. We recommend that your span, or standard calibration be performed at least half of the operating range limit. For example, on a 0-5ppm range analyzer your grab sample span calibration should be done with about a 2.5ppm solution.

-

As shown in the first photo above the difference between zero (0.001 VDC) and 1.439 PPM was 2.068 VDC. If the chlorine standard was set at X PPM at say 0.200VDC, the readings would be "jumpy" or erratic because a minute change in voltage will result in a large change in your PPM reading. Your reading will be correct, but you will see wide swings in residual on your chart or SCADA plot.

-

Don't use deionized or distilled water to set the zero point. These will likely generate no current. When your process water is fed, any background voltage present that is not produced by chlorine will be interpreted as being chlorine, resulting in high readings. Always remove chlorine from your process water with a carbon filter, or take a sample before chlorine is injected for the most accurate zero point.

-

If you don't have a carbon filter installed, you should feed dechlorinated process water from a 5 gallon bucket with a small submersible pump. Don't simply pour water from a bottle. Remember that amperometric chlorine analyzers are flow sensitive and require a consistent flow rate.

- When you enter the calibration screen from the home page, the analyzer maintains the last measured residual milliamp output until you are finished calibrating and return to the Home page. This is intended to prevent disruption to your chemical feed control.

- Your calibration entry won't appear immediately upon returning to the Home screen, the analyzer will take several seconds to ramp up or down to your entry.

As part of a standard quality control procedure, we recommend the analyzer readings be verified using an accurate chlorine residual test instrument once every 7 days. In many applications, using a portable DPD colorimetric residual analyzer for routine calibration checks is sufficient to meet reporting requirements. For the utmost precision or in critical applications we recommend comparison with an amperometric titrator.

As part of a standard quality control procedure, we recommend the analyzer readings be verified using an accurate chlorine residual test instrument once every 7 days. In many applications, using a portable DPD colorimetric residual analyzer for routine calibration checks is sufficient to meet reporting requirements. For the utmost precision or in critical applications we recommend comparison with an amperometric titrator. In an effort to conserve water more of our customers are asking about reducing the sample flow rate into their amperometric chlorine residual analyzers.

In an effort to conserve water more of our customers are asking about reducing the sample flow rate into their amperometric chlorine residual analyzers.